|

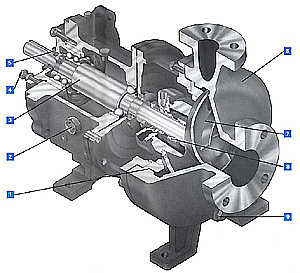

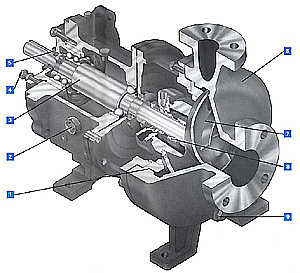

ProFlo

ANSI Pump

Specifications

1.

Positive

Sealing

Fully confined gasket at casing joint protects alignment from liquid.

2.

One

Inch Oil Sight Glass

Actual oil level and condition

easy monitored

3. Heavy Duty Shaft with Renewable

shaft sleeve

Maximum shaft deflection less than .002in. (.05mm) at face of the stuffing

box insures long seal and bearing life and low maintenance. A

hook-type shaft sleeve )available in a wide variety of corrosion resistant

materials) is free to expand with temperature variation.

4. Simple and fast external impeller

adjustment

Original high efficiency

maintained by impeller adjustment resulting in long term energy savings.

5. Labyrinth Oil Seal Standard

Carbon-filled PTFE labyrinth seals for chemical

resistance prevent premature bearing failure caused by lubricant

contamination and loss of oil.

6. Heavy Walled casing

- Top

Centerline Discharge for air handling, self venting.

- All

pumps have class 300 wall thickness as standard for longer life under

corrosive/erosive conditions. Resists high pipe forces and moments.

- Back

pull out design.

- Integral

feet.

7. Unique open impeller

With back pump-out vanes assure best performance and efficiency and lowest

NPSH requirements.

8. Maximum sealing flexibility

Choice of packed box or mechanical seal. Any type (cartridge or non

cartridge, inside or outside, single or double, balanced or unbalanced).

Almost any seal will fit without modification of the pump

9. Casing Drain Standard

Oil Lubrication Standard

Large oil chamber assures proper bearing temperature on high temperature

applications

ProFlow

ANSI Pump

Features

- ANSI B73.1M Standard Dimensions

- Maximum interchangeability

- Back-Pull-Out design permits quick

inspection of repairs of rotating elements without disturbing

electrical and piping connections

- Standard foundations save

installation drawing time, talent, and money

- Wide variety of metallurgy available

|